|

HOTLINKS to download

PAVE reports, review

upcoming NCAT training courses, query historical

weather data,

view current color radar or

preview

local forecast.

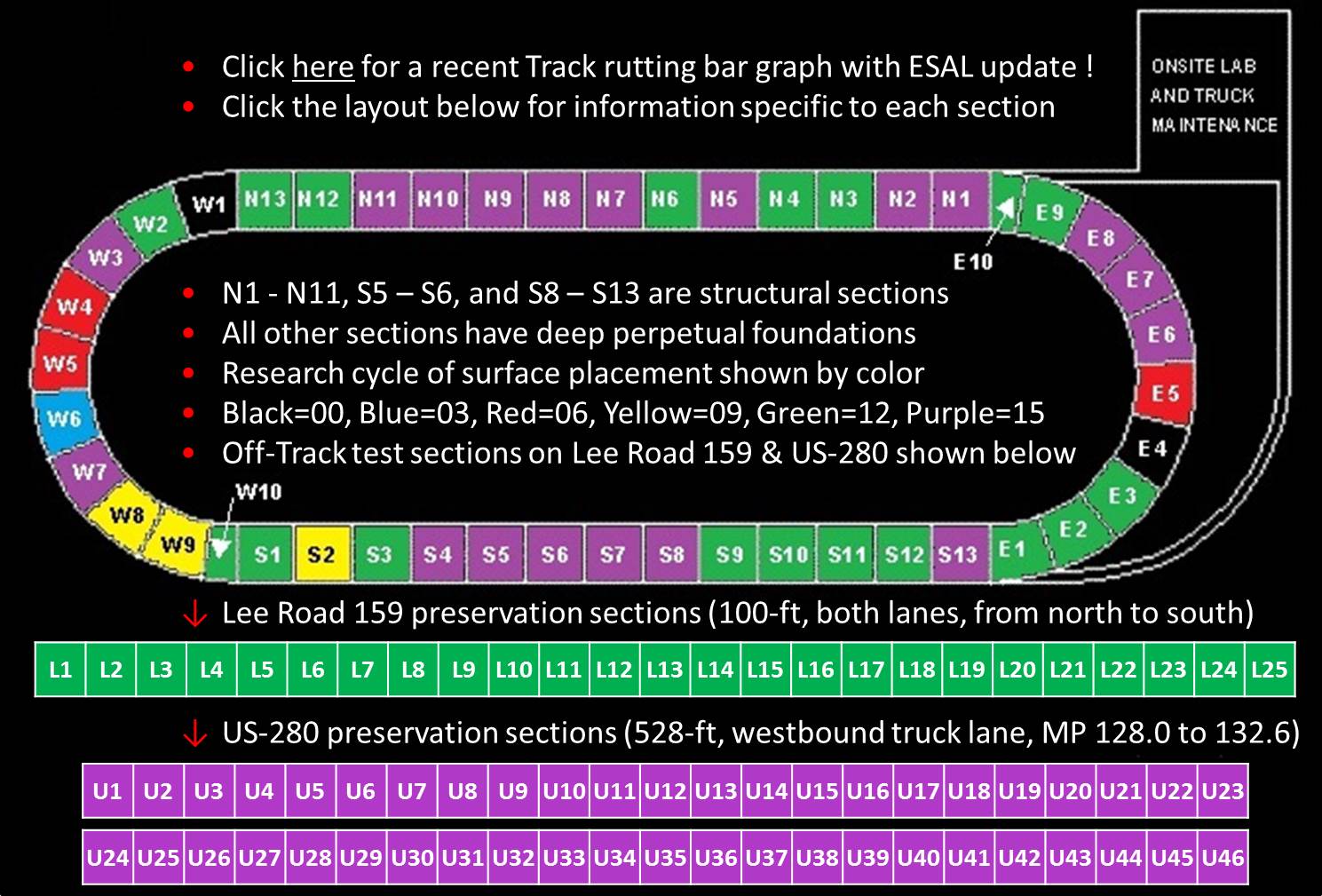

8,851,996 ESALs

on the Track as of 2300 hours on September 14, 2017 (89% of the 10,000,000

ESAL goal). Rut depths,

roughness, and macrotexture are measured every week. Detailed construction

and performance information for each section can be reviewed by clicking the

links shown near the top of this page. The web interface is an ongoing

effort. Please check back often!

CONTACT

this project via...

NCAT_Pavement_Test_Track

1600_Lee_Road_151 Opelika,_AL_36804_USA 334.844.7304

GOD BLESS AMERICA !

| |

| Performance data for each section will soon be available

for viewing by positioning your

mouse over the section in question and left-clicking. Based on feedback from our

research sponsors, the performance reports have been revised to include crack maps.

The 2012 performance reports will be a fully integrated and active part of the web

presentation.

|

| Every Monday, trucking is suspended so that vehicle maintenance can be performed and

pavement performance can be quantified. An inertial profiler equipped with a full

lane width dual scanning laser "rutbar" is run weekly around the entire Track in

order to determine individual wheelpath roughness, right wheelpath macrotexture and

individual wheelpath rutting for every experimental section. Additionally, 3 random

locations were selected within each section in a stratified manner to serve as the fixed

test location for nondestructive wheelpath densities. Transverse profiles are

measured along these same locations each week so that rutting may be calculated using a

contact method. Every month, wet ribbed surface friction testing, falling weight

deflectometer testing, and structural high speed response data is collected, along with

videologging to provide a permanent visual record of surface performance. Every

quarter, cores are cut from the wheelpath of every section so that densification of each

layer can be considered. |

| To facilitate lab to field performance correlations, numerous test specimens were

compacted using actual plant run material at the time test sections were constructed.

Additionally, hundreds of pounds of loose mix were sampled and saved during

production of each experimental section to facilitate other research projects that can be

enhanced by being plugged into Track research. |

|

![]()